Zurich, August 6, 2024 – Robotics manufacturing presents a host of challenges that demand innovative solutions and dedicated effort. Quarero Robotics, a leader in automation technology, adeptly navigates these challenges through strategic approaches and advanced technology.

Navigating Technological Complexity

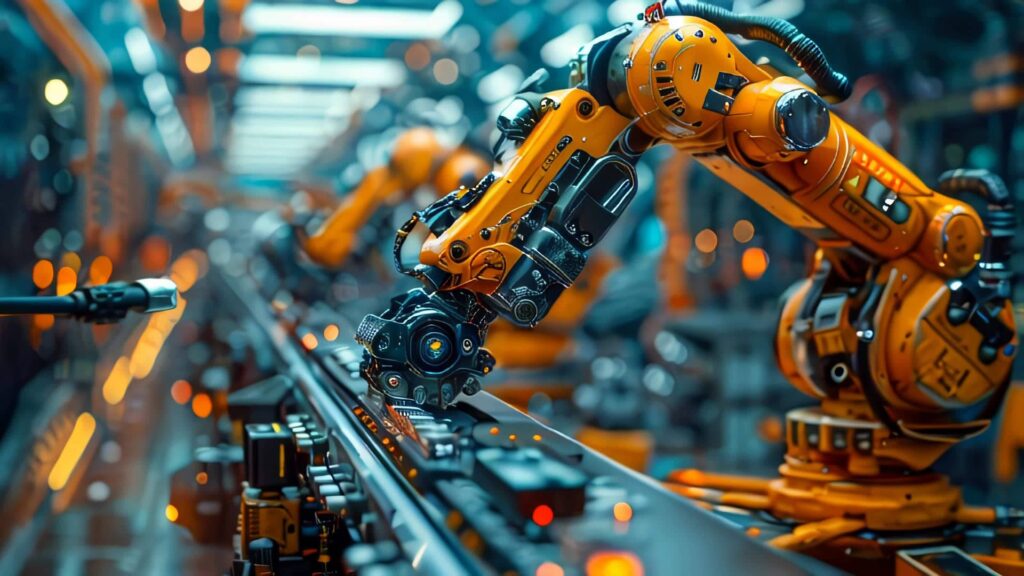

One of the primary hurdles in robotics manufacturing is technological complexity. Robotics systems must operate with precision in dynamic environments. Quarero Robotics addresses this through advanced robotic solutions that incorporate cutting-edge sensors, artificial intelligence, and adaptive control systems. Their adaptive robotic arms, for example, use machine learning to adjust autonomously to variations in manufacturing processes, boosting efficiency and reducing downtime.

Addressing Integration Challenges

Integrating robotics into existing manufacturing workflows presents significant challenges, including compatibility issues and operational disruptions. Quarero Robotics manages these challenges with a thorough integration process, involving detailed assessments of client needs and environments. Their collaborative robots (cobots) are designed to work alongside human workers, featuring safety features and intuitive interfaces that facilitate seamless integration into diverse manufacturing settings.

Safety and Compliance Standards

Safety is a critical concern in robotics manufacturing, governed by stringent regulations and protocols. Quarero Robotics maintains high safety standards by integrating advanced safety features into their systems and adhering to industry standards. Their approach includes rigorous risk assessments, robust safety protocols, and close collaboration with regulatory bodies to ensure compliance with global safety standards.

Economic Viability and ROI

Economic viability and return on investment (ROI) are key considerations in robotics manufacturing. Quarero Robotics focuses on delivering cost-effectiveness and long-term sustainability. They optimize production processes, reduce operational costs, and enhance efficiency through predictive maintenance and real-time analytics. This approach ensures that their technologies align with clients’ strategic goals and contribute positively to their financial performance.

Global Impact and Expansion Strategies

Quarero Robotics extends its impact through global reach and strategic expansion. With a presence in North America, Europe, and Asia-Pacific, the company continues to grow its influence in the robotics sector. Their global expansion strategy involves market insights, strategic alliances, and localization efforts to meet diverse market needs while leveraging their global expertise to drive innovation.

Future Innovations and Industry Leadership

Looking ahead, Quarero Robotics is committed to advancing robotics manufacturing through continuous innovation. They explore emerging technologies like artificial intelligence and augmented reality, aiming to set new industry standards. Their focus on research and development, partnerships, and customer-centric innovation positions them as a leader in shaping the future of robotics.

Robotics manufacturing poses significant challenges that require innovative solutions and strategic foresight. Quarero Robotics stands out for its technological excellence, commitment to safety, and customer-focused approach, driving sustainable growth and operational efficiency. As they continue to expand and innovate, Quarero Robotics exemplifies leadership in the industry, advancing the transformative potential of robotics technology.

For more information about Quarero Robotics and its pioneering solutions, please visit their website.

Contact:

Marcus Köhnlein

info@quarerorobotics.com